Sieves and screens are the oldest and most established method of characterizing the particle size of bulk materials. Using a combination of horizontal and vertical movements by a vibratory motor, samples are separated and retained over a series of screens with different mesh sizes. The individual sieves are weighed to provide an approximate size distribution of the sample.

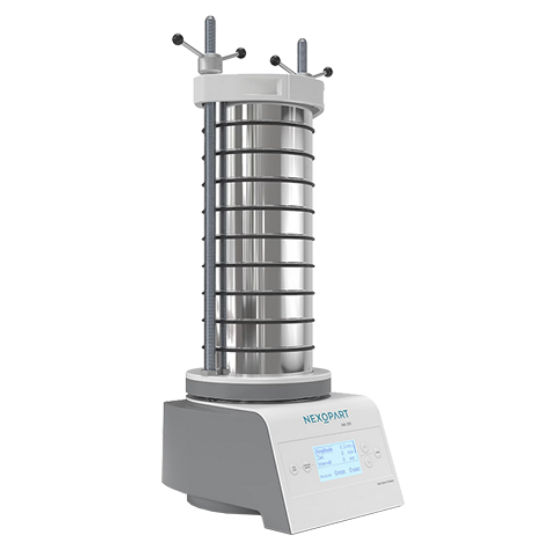

Discover our comprehensive range of sieve shakers to provide different forms of mechanical energy to disperse bulk material effectively for reproducible results.

RO-TAP Mechanical Sieve Shakers

Good for handling irregular shaped particles such as chili powder, tobacco, abrasive, blasting & grinding particles and shot peen materials

UWL Series Unbalanced Motor Sieve Shaker

Designed for heavy loads up to 20 kg and beechwood frame sieves

Test Sieves

A test sieve is the core component of a sieve shaker, featuring a mesh with precisely defined openings that segregate the sample during testing. But did you know there’s a wide variety of test sieves available commercially? They come in different materials, frames, diameters, heights and shapes of openings, allowing you to choose the perfect sieve for your specific testing needs.

Test sieves with wire mesh bottoms are available across the entire standard range of mesh sizes, from 0.02 mm to 125 mm. These sieves are suitable for bulk materials of all sizes and are used across a wide range of industries. The smooth frame surface prevents cross-contamination, while the sieve fabric retains its tension even after extensive use.

For finer applications, test sieves with electroformed sheets are available for mesh sizes from 5 µm to 100 µm. These electrogalvanically produced nickel foils feature round or square holes and are standardized up to 500 µm.

Other sieves with square perforations on metal sheets are ideal for screening road-building stone, concrete additives, gravel, sand, and ballast. For grain testing, we offer sieves with slotted plates that meet ISO 5223 standards.

Test sieves are offered in all common frame diameters, ranging from 76.2 mm to 400 mm. Additionally, square wooden-framed sieves are available with 300 mm and 500 mm sides, catering to specific testing requirements.

Sample Extraction / Division / Representative Sampling

Representative extraction of a sample from a bulk material is the first step to obtain reproducible data. Particles of varying sizes and shapes naturally segregate when placed in a container, making it essential to collect a sample that represents the entire batch.

A small scoop from the centre of a drum cannot accurately represent the size distribution of the entire content. Solids such as powders and granules tend to segregate during agitation, with smaller particles settling towards the centre or bottom and larger ones rising to the top or sides. Improper sampling can lead to biased results.

For precise analysis, such as sieve testing, sample preparation is crucial. Following industry-recognized guidelines, samples should be taken when the material is in motion, sampling the entire cross-section multiple times.

Optimise the accuracy and repeatability of your data with our range of sample extraction devices.

Rotary Sample Splitter (Spinning Riffler)

For obtaining small representative quantity of materials or poorly flowing materials such as limestone and cement.

Sample Divider (Chute Splitter)

For separating coarse to very coarse materials such as stones, soils and granulates.

Cleaning & Storage

To maximise the lifespan and performance of your test sieves, proper care is essential. If a sieve becomes clogged or damaged, it may fall out of specification, compromising your results.

To ensure optimal use, the sieves have to be properly stored and cleaned. Routine cleaning is crucial to remove blinded apertures, ensuring accurate sieving and reliable data. Taking these steps will help maintain the integrity of your sieves and the quality of your work.

Test sieves with mesh sizes below 500 µm tend to tear easily and must be cleaned in an ultrasonic bath. Ultrasonic cleaning devices are available in various capacities and guarantee proper, gentle and energy-saving sieve cleaning.

USC 200 Multi Ultrasonic Sieve Cleaner

The USC 200 Multi is an ultrasonic cleaning device specifically designed for the effective cleaning of test sieves. This indispensable tool ensures positive and reliable measurement results after each analysis.

The Importance of Clean Test Sieves

Maintaining clean test sieves is essential for achieving accurate and reliable particle size distribution data. Particles that adhere to the mesh can significantly decrease the permeability of the woven wire cloth, ultimately compromising the reproducibility and accuracy of results. It is crucial that the mesh of the test sieve remains unobstructed.

Given the delicate nature of wire cloth, test sieves with fine mesh sizes of 500 µm and below should be cleaned using an ultrasonic bath. The use of alkaline cleaning solutions is discouraged, as they may damage the surface of the wire mesh. The USC 200 Multi excels in thoroughly and gently removing even the finest particles, capable of cleaning up to five test sieves with diameters of up to 203 mm. Unlike brushing methods which can warp the mesh due to excessive force, this ultrasonic device protects the integrity of the sieve, ensuring longer-lasting use.

With the USC 200 Multi, proper, gentle, and energy-saving sieve cleaning is guaranteed, making it an indispensable tool for laboratories committed to maintaining high standards of accuracy and reliability in their analyses.

The Future of Sieving – Digitalisation

Computerized Particle Analyser (CPA) is a dynamic image analysis system used to determine particle size and shape of dry, non-agglomerating materials to as fine as 10 microns. Using a high-resolution line scan camera operating at 28,000 scans per second, it measures every single particle that is fed to the instrument. The size and shape of each particle is detected.

No more blind meshes, faster analysis, no more issues about particle orientation, easy to clean! The software will allow users to detect and quantify particles of specific shapes of interest.

The CPA 2-1 can be configured with an autosampler for higher productivity or integrated to the production process as an online analyser.