EML Series Electromagnetic Sieve Shakers

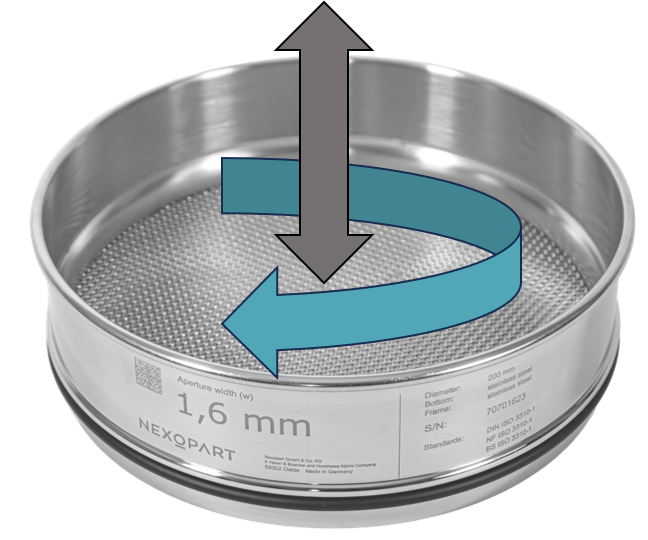

The EML 200 series of sieve shakers is a cutting-edge solution designed for precision and efficiency in particle analysis. Featuring an advanced electromagnetic drive, these shakers operate with remarkable robustness and quietness, ensuring a versatile performance that meets the demands of laboratories. The EML 200 series excels in 3D sieving, effectively pushing materials vertically out of the meshes while distributing them horizontally in a circular motion across the entire mesh surface. This innovative design guarantees excellent reproducibility and accuracy, all while being practically maintenance-free.

How It Works

The EML 200 is electromagnetically driven to provide 3-dimensional sieving action for fast and optimally reproducible results. The sample will be evenly distributed over the entire sieve surface area to ensure optimal use of the sieve openings. The system holds up to 9 test sieves with normal height (50 mm) or 15 test sieves with reduced height (32 mm) and a sieve pan. Test sieves with meshes from 20 µm to 125 mm can be provided.

Good Looks and Performance

The EML 200 is built with a sleek minimalist aluminium housing with a cover that has an inspection glass to allow samples to be observed during sieving.

There are 2 models available for dry sieving – the EML 200 Pure for general applications and the EML 200 Premium for users who require highly precise and repeatable data. Both models are suitable for test sieves of diameters from 50 to 203 mm. Up to 3 kg can be analysed in a single test.

The EML 200 series offer 2 types of clamps designed to securely hold the sieve stack in place. The classic clamp requires the user to screw across the guiding rod to the lid and tighten the clamp into position. In contrast, the Twin Nut clamp offers enhanced convenience, allowing for easy adjustment to the appropriate height of the lid without the need to rotate the clamp along the vertical height of the guiding rod. This thoughtful design ensures a more efficient and user-friendly experience during operation, especially if only a few test sieves are used.

Classic Clamp

Twin Nut Clamp

EML 200 Pure

The EML 200 Pure is a plug & play system whereby the user will only need to select the amplitude mode (fine or coarse material) and the timer to begin the analysis.

Two regulated amplitudes to select from: Fine or Coarse materials

Automatic readjustment of amplitude

Fixed intervals of 10 seconds

Digital timer: 0 to 99 min or constant operation

Classic “eco” clamping system

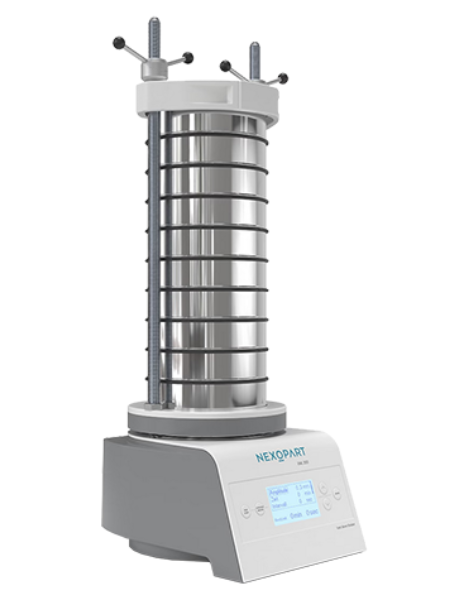

EML 200 Premium

The EML 200 Premium has an improved dampening system to significantly reduce the transmission of vibrations, allowing the system to operate quietly. The extra-large display offers the user a simple and user-friendly interface. The amplitude can be adjusted up to 3 mm. An ethernet port is included for data transfers to a computer and integration with LIMS. The new EML 200 Premium is ideal for users who demand precision and reproducible sieve analyses.

Extra quiet electromagnetic drive

Free selectable amplitude up to 3 mm

Improved damping system for quiet operation

Ethernet interface

Extra large, easy to use display

Up to 49 different sieving programs can be stored in the memory

Twin Nut clamping system for convenient clamping

EML 200 Premium Remote

The EML 200 Premium Remote designed to facilitate both wet as well as dry sieving. Equipped with a cover and pan that feature a full cone nozzle, hoses and a discharge nozzle, the instrument effectively utilises water to assist in separating and sieving particles that may be clumping or sticking together. The introduction of water into the sample not only aids in particle separation but also eliminates static charge, allowing for accurate passage through the sieve openings.

An inspection glass integrated into the cover provides a clear view of the material during the sieving process, ensuring that monitoring is both convenient and effective. Deaeration rings can be added to the sieve stack to vent the air between the individual sieves to prevent air pockets from being formed. Once the sieving is complete, the samples are dried and weighed for precise analysis.

The drive unit is designed with a protection class of IP 54, safeguarding it against splashes of water. Additionally, the control module can be conveniently mounted on a wall, minimizing the risk of water damage to sensitive components.

The EML 200 Premium Remote accommodates sample quantities of up to 3 kg and supports test sieve diameters ranging from 50 to 203 mm. It is well-suited for handling samples such as agricultural soil with high clay content, clay suspensions, kaolin and marine or river sediments.

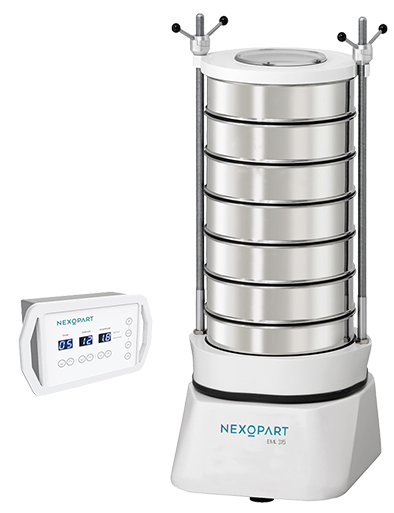

EML 315 Digital Plus

If a higher sample quantity needs to be sieved for better representation, the EML 315 Digital Plus is a robust floor-standing model designed to accommodate larger test sieves with diameters of 300, 305 (12”) and 315 mm. It can hold a maximum of 7 full-height test sieves along with one pan, or up to 13 half-height test sieves and a pan, allowing for a substantial sample capacity of up to 6 kg.

The control panel is thoughtfully designed to be separated from the shaker and can be conveniently wall-mounted at a comfortable height. This ensures that operators do not have to bend down to reach the controls, enhancing usability and ergonomics during operation. Additionally, an inspection glass is integrated into the lid, providing a clear view of the sample during the sieving process.

It is available in 2 versions – for dry or wet sieving.

EML 450 Digital Plus

For sieving coarser or larger quantities of material, the EML 450 Digital Plus stands as the largest sieve shaker featuring an electromagnetic drive. It is capable of accommodating the biggest test sieves with diameters of 400 or 450 mm. It can hold up to 13 full-height sieves along with one pan, allowing for a maximum sample weight of 15 kg.

The control panel is thoughtfully separated from the shaker and can be conveniently wall-mounted at a comfortable height. This design ensures that operators do not need to bend down to access the controls, enhancing usability and ergonomics during operation. Additionally, an inspection glass is integrated into the lid, providing a clear view of the sample throughout the sieving process

It is available in 2 versions – for dry or wet sieving.