Bettersizer 2600

The Bettersizer 2600 is a particle size analyser based on the principles of Laser Diffraction and complies to ISO 13220. It can be used to measure particles suspended in a liquid or in dry powder form.

Samples are loaded onto either a dry dispersion or wet dispersion module. This module feeds the sample into the Bettersizer 2600 for analysis. The instrument measures the angle and intensity of scattered light as a laser beam passes through a dispersed sample. The signals are processed via Fraunhofer or Mie algorithm to calculate the particle size distribution.

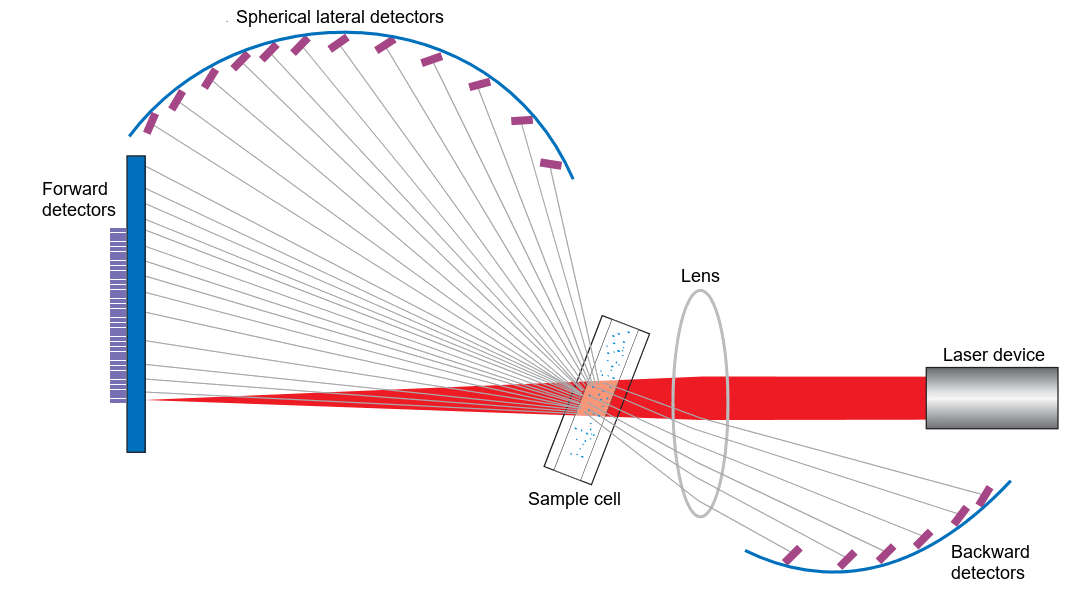

Unique Optical Arrangement For Wide Measurable Size Range

The Bettersizer 2600 features a patented optical arrangement that combines the use of both Fourier and reverse Fourier optics to cover 0.016 to 165° angles of detection. The sample cell is also tilted at an angle of 35° to avoid internal reflection of the light. This allows the instrument to measure both small and large particles at the same time - from 0.02 μm to 2,600 μm.

The Bettersizer 2600 features a fibre laser that is thermally stable and has long operational lifespan. It does not require instrument warm up before operation.

Powerful Centrifugal Pump To Circulate Samples Of Higher Densities

The BT-802 wet dispersion module can handle particles with high densities. The flow rate of the centrifugal pump ranges from 3 to 8 L/min (45 adjustable speeds), to ensure that large particles of high densities can be suspended and circulated through the system.

Powerful Sonicator For Breaking Up Agglomerated Particles

The BT-802 features a built-in sonicator of 50 W power (50 adjustable levels) & 38 kHz frequency with dry-burn protection. This powerful sonicator helps to break up agglomerated particles to ensure that primary particles are measured. The dry-burn protection protects the transducers from overheating if the system is accidentally left running without any liquid.

Illuminated Dispersion Bath

The BT-802 includes an ergonomically positioned LED light that illuminates the sample dispersion bath to make it easy to introduce the sample and observe the dispersion process.

Minimise Risk Of Fire When Analysing Dry Pyrophoric Powders

Some fine powders, such as metals, are pyrophoric when dispersed in dry air. This presents a fire hazard in other competing models as the dry powder is drawn by vacuum through a venturi nozzle and dispersed using dry compressed air.

The BT-902 includes selective components that prevent dry powders from accumulating and igniting.

Minimise Risk Of Fire When Analysing Dry Pyrophoric Powders

The Bettersizer 2600 was designed to make it simple to switch between the wet and dry dispersion modules. The operator does not need to handle the delicate sample cells during the exchange. The operator also does not need to switch calibration files in the software.

The operator would only need to lift up the cell holder on the Bettersizer 2600 and replace it with the alternate cell holder, without worrying about tubings and cables. The sample circulation path was designed to be a closed loop. Therefore, there will not be any spills or leaks that might affect the electronics while switching between the dispersion modules.

Refractive Index Measurement to Determine Real and Complex Refractive Indices

The Bettersizer 2600 software features calculation models based on both Fraunhofer Approximation and Mie Theory. Fraunhofer Approximation is appropriate when the particles are above 50 μm, spherical and opaque. Mie Theory is typically used in modern day laser diffraction instruments because of its accuracy and suitability for measuring both sub-micron particles as well as large particles. However, Mie Theory can sometimes be challenging because the operator needs to know the real and complex refractive indices of the sample before the analysis.

Refractive Index Measurement

The Bettersizer 2600 software includes a patented Refractive Index Measurement function to help the operator determine the appropriate optical parameters to use for the particle size analysis. This is especially helpful if the refractive index of the sample cannot be easily found in literature sources. The analysis is easy to perform and only takes a few seconds.

Bettersizer S3 Plus

The Bettersizer S3 Plus is a 2-in-1 instrument that combines Laser Diffraction and Dynamic Image Analysis to provide particle size and shape analysis. While Laser Diffraction is an industry-accepted technique for size analysis and offers a wide size range, Dynamic Image Analysis offers insight into the morphology of the particles and acts an independent referee technique for data validation.

Samples are introduced into the dispersion module, which feeds the sample into the Bettersizer S3 Plus for the analysis. The sample passes through a sample cell where it is subjected to a beam of light and the angle and intensity of scattered light are measured. The sample flows into a separate flow cell where two high speed CCD cameras, with 0.5X magnification and 10X magnification, are used to continuously take pictures of individual particles. The data signals are processed in the software to provide a particle size distribution of the sample, as well as individual pictures of the particles. The software applies certain calculations to classify the pictures of the particles according to multiple shape parameters.

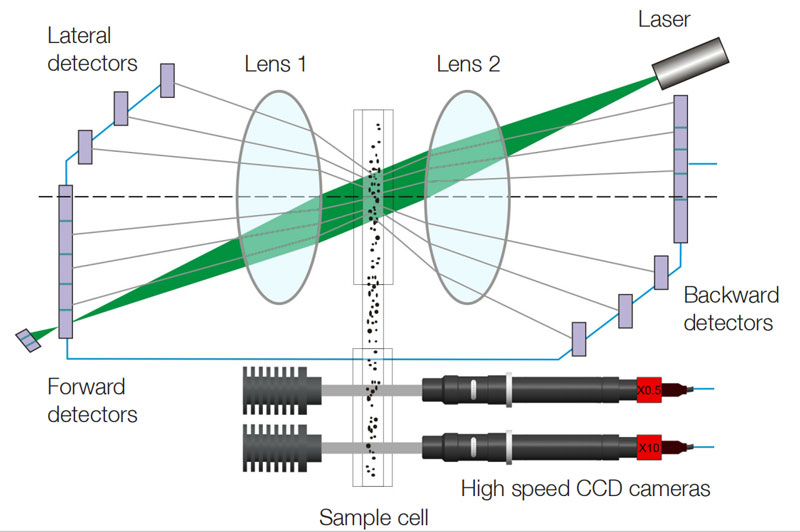

Unique Optical Arrangement For Wide Measurable Size Range

The Bettersizer S3 Plus features a patented optical arrangement called Dual Lens & Oblique Incidence Optical System (DLOIOS).

Conventional Fourier optics offer high resolution and precision. However, it is unable to detect the high angles of scatter produced by smaller particles.

Reverse Fourier optics produce a convergent incident beam that allows the instrument to capture high angles of scattered light. However, this presents a drawback where there are fewer detector channels available on the forward detector, which leads to lower resolution and sensitivity to differentiate larger sized particles. The particles must also flow in a narrow stream due to focal length tolerances.

DLOIOS places the sample cell between two Fourier lenses, whereby the second lens overcomes the limitation of conventional Fourier optics to allow a wide angle of measurement from 0.02 to 165°. A 532 nm green diode-pumped solid-state laser (DPSSL) is used to increase the intensity of the scattered light produced by small particles for better sensitivity. It eliminates the need to have multiple lasers and switching between different light sources during the measurement. As a result, both small and large particles can be measured at the same time - continuously.

Powerful Centrifugal Pump To Circulate Samples Of Higher Densities

The BT-803 wet dispersion module can handle particles with high densities. The flow rate of the centrifugal pump ranges from 3 to 8 L/min (45 adjustable speeds), to ensure that large particles can be suspended and circulated through the system.

Powerful Sonicator For Breaking Up Agglomerated Particles

The BT-803 wet dispersion module features a built-in sonicator of 50 W power (50 adjustable levels) & 38 kHz frequency with dry-burn protection. This powerful sonicator helps to break up agglomerated particles to ensure that primary particles are measured. The dry-burn protection protects the transducers from overheating if the system is accidentally left running without any liquid.

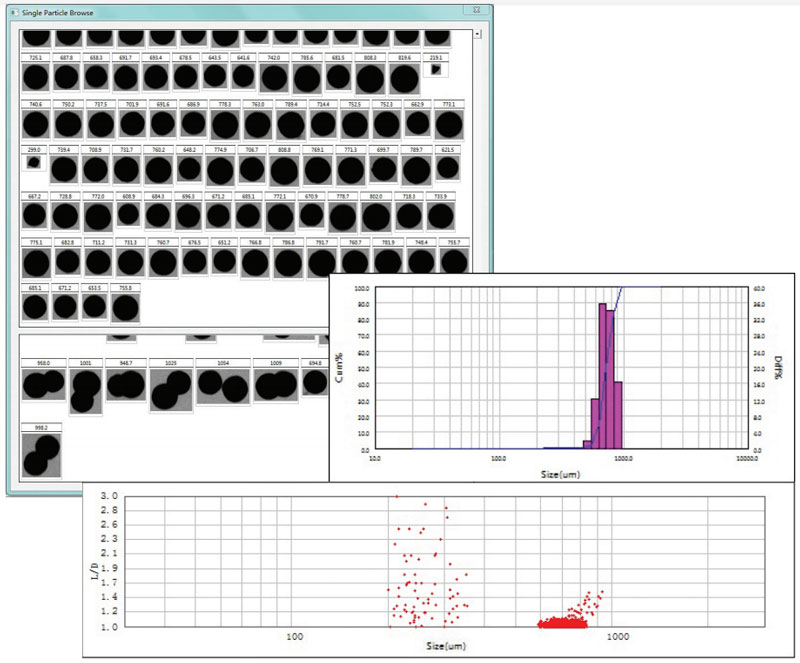

Better Sensitivity For Oversized Particles

The Bettersizer S3 Plus incorporates dynamic image analysis as a strong complement to laser diffraction. Laser diffraction is an ensemble technique that provides data based on volume distribution while Dynamic image analysis takes pictures of individual particles and classify them into various geometries based on a number distribution. This allows Dynamic image analysis to offer a better resolution and sensitivity at detecting trace levels of oversized particles in the sample.

Morphological Parameters To Characterise The Bulk Behaviour Of Particles

Sample materials can exhibit different physical behaviour without a significant change in particle size distribution. Particle morphology provides additional information that influences the bulk behaviour of the particles, such as dissolution, packing density, flow and encapsulation. The Bettersizer S3 Plus offers 23 size & shape parameters such as aspect ratio, Feret diameter, circularity, convexity, solidity, elongation, compactness, ellipse ratio, greyscale etc, as according to ISO 9276-6. Differences in shape can be used to detect contaminants from the manufacturing process that may be present in the sample.