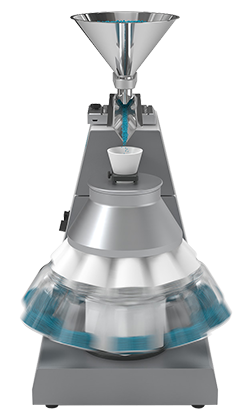

Rotary Sample Splitter

The Rotary Sample Splitter, or Spinning Riffler, is an essential tool for the precise preparation of bulk material samples for subsequent analysis. Engineered to deliver small yet representative samples of solids and suspensions, this device is ideal for use in laboratories focused on research & development or quality control.

The RPT series combines three advanced splitting processes within a single unit, achieving unparalleled standard deviation of less than ±0.5% between each collection bottle.

How It Works

The RPT series processes a maximum bulk material quantity ranging from 300 ml to 4,000 ml, accommodating particle sizes up to 2.5 mm or 10 mm, depending on the selected model. The process begins as bulk material is poured into a hopper that feeds it into a rotating cone. Here, the material is accelerated outward and divided through guide channels into 8, 10, or 30 individual screw cap glass bottles. These bottles are available in various capacities from 15 ml to 500 ml and are easily secured using a quick-acting clamping device, ensuring safe handling and efficient cleaning.

With variable division ratios of up to 3,000 division steps per minute achievable through adjusting rotation speeds and the number of collection bottles, the RPT allows for equal distribution of large sample quantities into multiple representative samples suitable for diverse laboratory analyses. This capability extends even to poor-flowing materials such as cement and limestone, ensuring high precision across all applications.

All components of the RPT series are made from food-safe materials, ensuring ease of cleaning and hygiene. Additionally, the device features a low-maintenance drive motor equipped with a slip clutch, enhancing its reliability and performance.

The RPT series plays a crucial role in generating highly reproducible data in the laboratory, as it guarantees that samples are consistent and representative of the bulk material. This device is an indispensable asset for any laboratory that processes dry powdered materials, ensuring accuracy and reliability in all types of analyses.

RPT 1:8

The RPT 1:8 divides the bulk material into 8 glass bottles. This model produces the largest quantity of sample in each bottle, which can be used for various physicochemical tests that require a larger amount of sample.

· Max bulk material quantity of 4,000 ml

· Max particle size of 10 mm

· Glass bottle capacities of 250 or 500 ml

RPT 1:10

The RPT 1:10 divides the bulk material into 10 glass bottles. The quantity of sample produced in each bottle is sufficient for most sieve shakers.

· Max bulk material quantity of 2,500 ml

· Max particle size of 10 mm

· Glass bottle capacity of 250 ml

RPT 1:30

The RPT 1:30 divides the bulk material into 30 glass bottles. This model produces the smallest quantity of samples that are appropriate for all kinds of analysis techniques such as laser diffraction, air jet sieve and physisorption. The large number of samples produced is especially useful if performing the “Swiss Method” of air jet sieving.

· Max bulk material quantity of 300 ml

· Max particle size of 2.5 mm

· Glass bottle capacities of 15, 20 or 30 ml